UPSC

PIB

Capital Goods Revolution under Make in India: Boosting Economic Resilience

Last Updated

3rd April, 2025

Date Published

3rd April, 2025

Share This Post With Someone

Released on April 2, 2025, by the Press Information Bureau under the Ministry of Commerce, this document details the transformative impact of the Make in India initiative on India’s capital goods sector. It highlights policy interventions, production growth, and technological advancements, offering critical insights into industrial development, economic strategy, and governance for aspirants preparing for competitive exams.

Key Points

- Publication Details: Issued by the Research Unit, Press Information Bureau, Government of India, under the Ministry of Commerce on April 2, 2025.

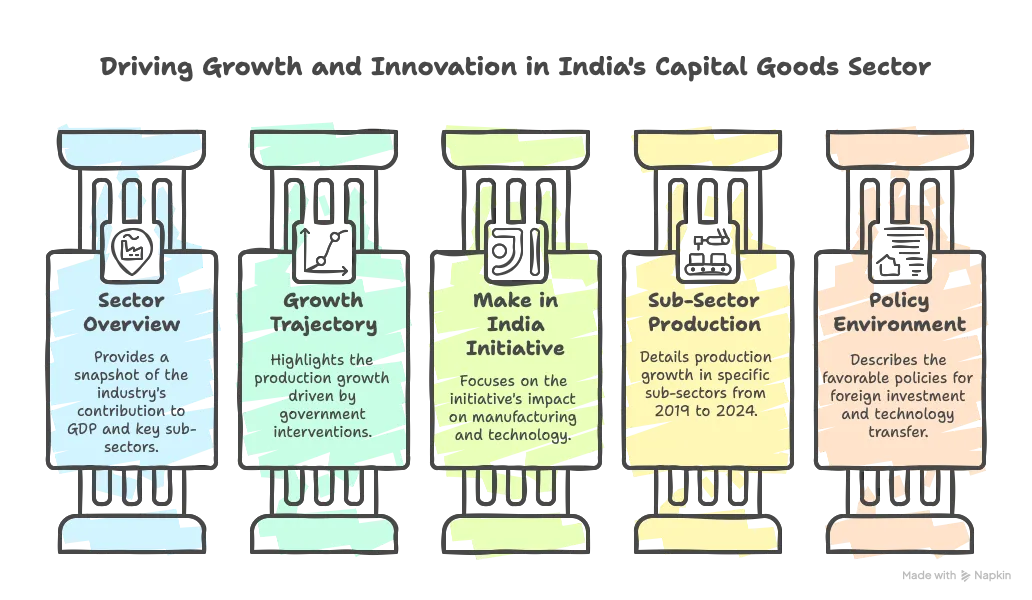

- Sector Overview: The capital goods industry, encompassing heavy engineering and machine tools, includes sub-sectors like dies, moulds, textile machinery, and earthmoving equipment, contributing 1.9% to India’s GDP.

- Growth Trajectory: Production rose from Rs. 2,29,533 crore in 2014-15 to Rs. 4,29,001 crore in 2023-24, driven by Ministry of Heavy Industries’ interventions.

- Make in India Initiative: Launched in 2014, it aims to elevate manufacturing’s GDP share, create jobs, and enhance technological capabilities, with capital goods as a cornerstone.

- Electrical Equipment Boom: The Indian Electrical and Electronics Manufacturers’ Association (IEEMA) reports double-digit growth in power equipment, especially transmission and transformers, due to domestic and global demand.

- Construction Market: India ranks as the third-largest market for construction equipment, fueled by urbanization and infrastructure projects.

- Sub-Sector Production (2019-24):

- Machine Tools: Rs. 6,152 crore (2019-20) to Rs. 13,571 crore (2023-24).

- Earthmoving and Mining Machinery: Rs. 31,020 crore (2019-20) to Rs. 73,000 crore (2023-24).

- Printing Machinery: Rs. 12,678 crore (2019-20) to Rs. 23,479 crore (2023-24).

- Export Growth (2019-24):

- Textile Machinery: Rs. 2,556 crore (2019-20) to Rs. 4,451 crore (2023-24).

- Process Plant Equipment: Rs. 8,330 crore (2019-20) to Rs. 9,140 crore (2023-24).

- Earthmoving and Mining Machinery: Rs. 3,583 crore (2019-20) to Rs. 5,800 crore (2023-24).

- Policy Environment: No industrial license required; 100% FDI allowed via automatic route (except from bordering countries); unrestricted technology transfer payments and trade.

- Union Budget 2025-26: Proposes exemptions for 35 additional capital goods for EV battery manufacturing and 28 for mobile phone batteries to boost domestic lithium-ion battery production.

- National Capital Goods Policy (2016):

- Aims to raise manufacturing contribution from 12% (2016) to 20% by 2025.

- Targets doubling production and increasing exports to 40% of output.

- Focuses on advancing technology from basic to cutting-edge levels.

- Policy Features:

- Increased budget for competitiveness scheme, adding skills, capacity building, and advanced manufacturing.

- Technology Development Fund (PPP model) for tech acquisition and IPR purchases.

- Regional Centres of Excellence for skill development.

- Modernization of SMEs with energy-efficient machinery.

- Upgraded testing and certification infrastructure.

- Scheme Phase I (2014):

- Outlay: Rs. 995.96 crore; sanctioned 33 projects (Rs. 583.312 crore).

- Outcomes: 8 Centres of Excellence (30 indigenous technologies), 15 Common Engineering Facility Centres (including 4 Industry 4.0 SAMARTH centres), 6 Technology Innovation Platforms (76,000+ registered users), 5 tech acquisitions from abroad.

- Integrated Machine Tools Park: 145 of 336 acres allotted in Tumakuru, Karnataka.

- Scheme Phase II (2022):

- Outlay: Rs. 1,207 crore (Rs. 975 crore government, Rs. 232 crore industry); 33 projects sanctioned (Rs. 1,366.94 crore total, Rs. 963.19 crore government).

- Components: 9 new Centres of Excellence (Rs. 478.87 crore), 5 CEFCs (Rs. 357.07 crore), skilling projects (Rs. 7.59 crore), 7 testing centre upgrades (Rs. 195.99 crore), 8 industry accelerators (Rs. 325.32 crore), support for 6 innovation platforms.

- Fund Allocation (2014-25):

- 2014-15: Rs. 24 crore allocated, Rs. 2.80 crore released.

- 2022-23: Rs. 199.60 crore allocated, Rs. 199.24 crore released.

- 2024-25: Rs. 184 crore allocated, Rs. 134.55 crore released (as of February 3, 2025).

- Recent Achievements:

- Sitarc, Coimbatore: 6-inch BLDC submersible pump (88% motor efficiency), reducing imports by 80%.

- CMTI: High-speed rapier loom (450 RPM) launched at ITMA 2023, Milan.

- ARAI, Pune: Battery and BMS testing facility established.

- I-4.0 India @ IISc: Developed 6 smart technologies, 5 tools, 14 solutions in robotics, digital twin, etc.

- ARAI-AMTIF: High-voltage motor controller and sodium-ion batteries developed.

- BHEL Contributions:

- CEFC for welding skill development at Trichy, with extensions in Varanasi, Ranipet, Bhopal, Jhansi, and Haridwar.

- Testing facility with HIL and SIL functionalities at Hyderabad R&D unit.

- Conclusion: Make in India has enhanced domestic production, competitiveness, and job creation in the capital goods sector, positioning it for sustained growth with ongoing policy support.

Glossary

- Capital Goods: Machinery and equipment used in production, critical for industrial growth.

- Make in India: 2014 initiative to boost manufacturing’s GDP share and technological prowess.

- Ministry of Heavy Industries: Oversees policies to enhance capital goods production.

- FDI: Foreign Direct Investment, allowed up to 100% in capital goods via automatic route.

- National Capital Goods Policy (2016): Framework to double production and advance technology by 2025.

- Centres of Excellence (CoE): Research hubs developing niche indigenous technologies.

- Common Engineering Facility Centres (CEFC): Facilities for training, R&D, and industry support.

- Technology Acquisition Fund: PPP model fund for acquiring advanced technologies.

- Industry 4.0: Integration of smart technologies like IoT and robotics in manufacturing.

- Aatmanirbharta: Self-reliance, a key goal of reducing import dependence in capital goods.